Frank Pleszak

We all knew that there were coal mines in this area during the heyday of the Industrial Revolution but they closed long ago, before the First World War. Or did they? Not according to Frank Pleszak who gave us the history of a mine on Ludworth Moor which was worked from 1927 until 1983 under various ownership. Not only that, but he brought with him Rod Thackray, the very last miner.

Tramming tubs of coal to the surface (Andersen Shelter tunnel) -1940’s Ludworth

This was not the type of coal mine seen in films or books - the pit head buildings with the headstock winding gear outlined against the sky, the rows of miners with their helmets and lamps and the ubiquitous spoil heaps of material that was extracted in order to get at the coal. No, this was a much smaller and less capital intensive operation. It was small-scale, using traditional methods and, at least until its final days, unobtrusive in the landscape. This was the sort of coal mine that Samuel Oldknow operated. The mine that George Andrew had in Etherow. But certainly not the coal mines of South Lancashire that gave the Legh family of Lyme their great wealth.

Bradford Colliery, Manchester - 1926

But first Frank put this mine into the context of the national coal industry. Coal has been mined in Britain since Roman times with these early miners extracting coal already exposed on the surface then following the seams underground. Coal production increased dramatically in the nineteenth century as the industrial revolution gathered pace needing fuel for steam engines and then later, for the railway network. Coal was also widely used for domestic heating owing to its low cost and widespread availability. The manufacture of coke also provided coal gas.

The early mines were drift mines or shallow bell pits but as technology improved, by 1750 coal seams were being accessed by vertical brick-lined shafts. Production peaked at 287 million tons in 1913 and the industry employed 1.2 million men but after that date both declined in tandem. There was a significant change in the structure of the industry in 1947 when almost all mines were nationalised and run by the new body, the National Coal Board but the decline of the industry continued and the increasing evidence of climate warming and the pollution caused by burning coal have both hastened its demise.

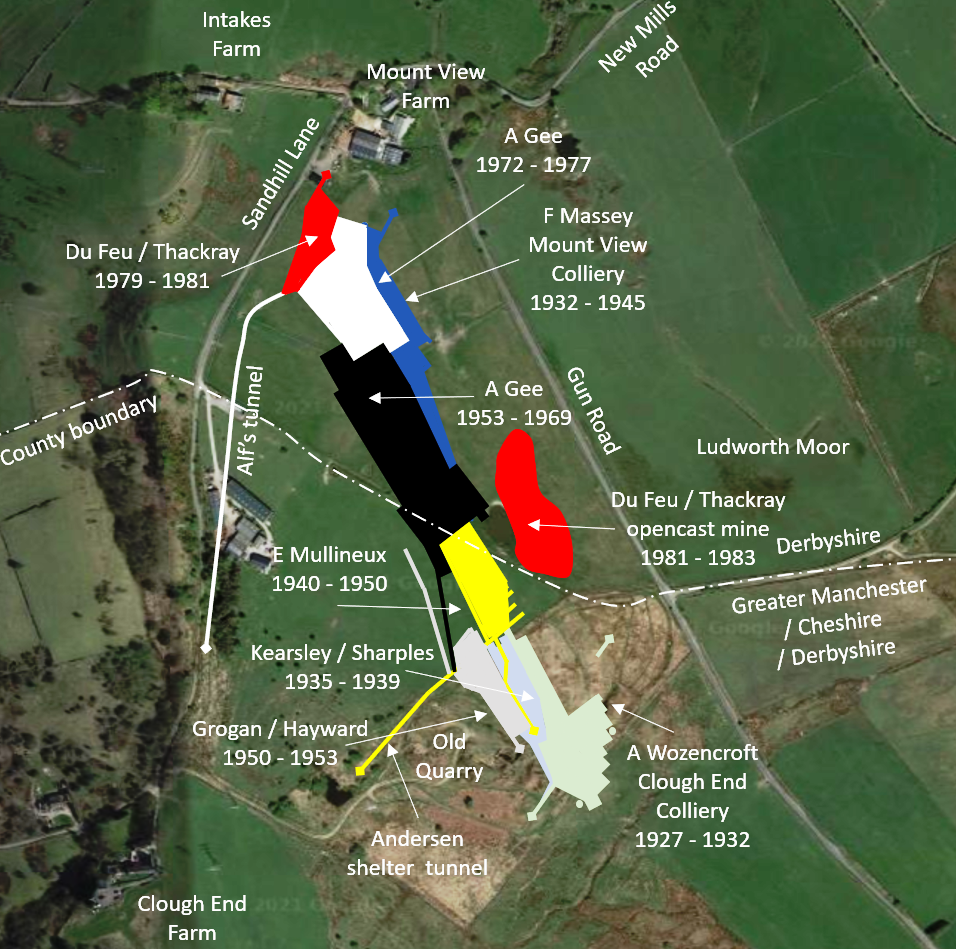

The Ludworth colliery began in the early 1920s when a local farmer, Eric Humphreys, worked an outcrop with the help of his wife and father. A few years later another farmer, Mr Wozencroft of Clough End Farm opened the eponymous Clough End Colliery. This was a more ambitious venture, employing an experienced miner and constructing a 50 yard adit to the coal seam. This enterprise employed up to six men and produced between four and five tons of coal each day. This was sold to local mills. However, it never produced a good return and when his wife fell ill Mr Wozencroft decided to call it a day in March 1932.

At roughly the same time another colliery opened by the Massey family on their land on Sandhill Lane. Two brothers had been digging a pond on their father’s land when they accidentally happened upon a coal seam. One of the brothers was an experienced miner so he organised an operating unit using local unemployed workers but only some had experience in mines. They were paid 12/6d a ton and the coal was sold at between 19 shillings and 23 shillings a ton, depending on the quality. On this basis the miners regularly earned about £3 per week which does not sound much but compares with wages of 45/- for a six-day week in the local mills. The war disrupted the business as several employees were called up and at the end of the war the two Massey brothers could not agree the division of future profits. They were both in their seventies so they decided to close the mine.

Another mine had opened nearby at the start of the war. Lord Howard who owned the mineral rights gave permission to E. Mullineux to reopen the Ludworth Moor colliery and he was both experienced in mining and had adequate capital to finance his plans. Before long four face workers were producing seventy tons per week and the demand for coal during the war ensured healthy profits. The coal was sold to various local businesses and, as a bonus, twenty tons of fireclay were also produced each week which found a ready market. However, the closure of the Mount View mine in 1945 produced problems because it was higher than Ludworth and accumulated water seeped down into Ludworth. Worse was to come as his son Eric was drowned in a new shaft that they were sinking, having been overcome by black damp (carbon dioxide.) His heart went out of the business and by 1953 one of his employees, Alfred Gee had taken control but with little financial backing.

Alf Gee outside ‘Alf’s tunnel’ 1979 (photo by Geoff Cusick)

Although most mines were nationalised in 1946, very small operations such as these remained independent though controlled by the NCB for safety regulations and expansion plans. Mr Gee had to develop new coal reserves as the old seams were worked out so he worked in a quarry to produce an income and drove a new adit to access coal in his spare time. At first he was selling coal to customers who arrived at the mine and rang a bell to attract his attention but volume gradually built up but this was at a time when the big collieries were in decline. In order to protect employment the NCB operated a quota system and Ludworth was given a derisible figure of 100 tons per year. Fortunately an appeals tribunal raised this to 306 tons so the mine was able to survive - just.

Rod Thackray and Geoffrey du Feu at the coal screen 1981 (photo by Geoff Cusick)

By 1978 Alf Gee was getting tired and he sold his interest in the mine to two mining engineering students, Tony Lodge and Geoffrey du Feu. The first few months were hard and Tony Lodge decided it was not for him but duFeu persisted, with the help of the original owner, Alf Gee, and gradually built up production. Rod Thackray who was with us at the meeting joined the team and for several years the mine prospered, with coal sales to various enterprises and their own coal yard for domestic sales in New Mills. When the accessible underground seams were exhausted in 1981 a licence was granted for open cast mining and this produced good coal with the help of big machinery for the remaining two years.

The workings eventually closed in 1983 and today there is no trace of what used be an active mining area for over fifty years. But we still have Rod Thackray who has given both memories, advice and even artefacts to museums in the north west and has helped to design the life size model of a mine at New Mills Heritage Centre. It cannot claim to compare with the National Mining Museum in Wakefield but it shows the reality of a very different type of coal mine - one that would be well known in the early days of the Industrial Revolution.

Geoff Cusick and Rod Thackray above what was the entrance to the Andersen Shelter tunnel

Geoff Cusick and Rod Thackray above what was the entrance to the Andersen Shelter tunnel